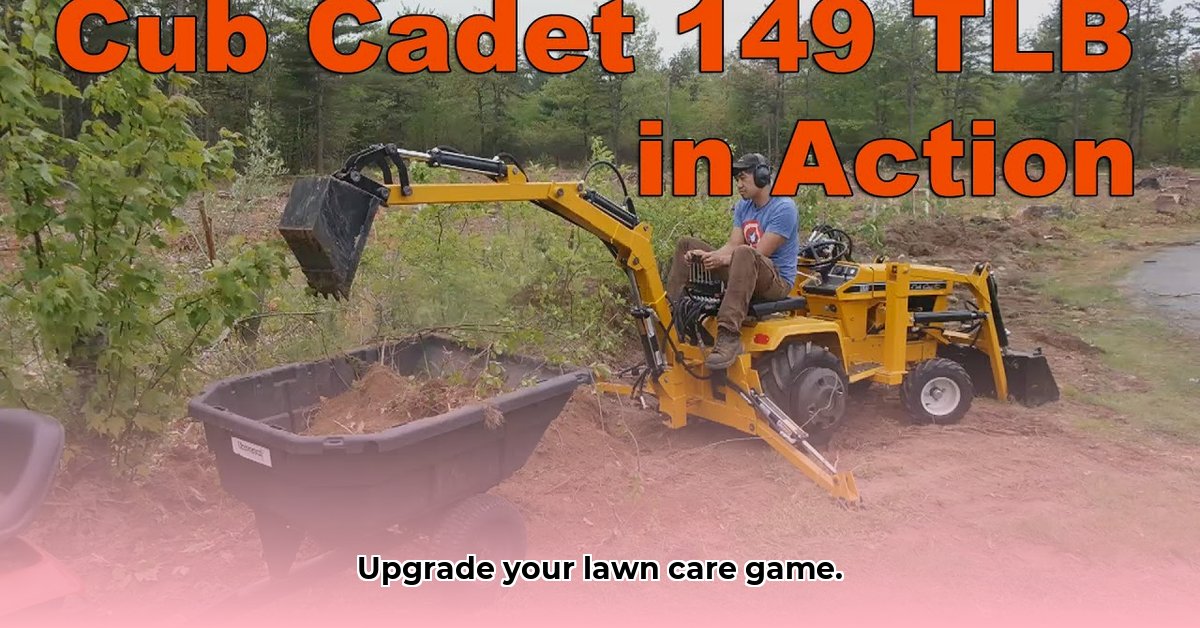

Adding a backhoe or front-loader to your lawn tractor can significantly boost your yard work efficiency. But choosing the right attachment and ensuring safe installation are crucial. This guide will help you navigate the process, from assessing your tractor's compatibility to maintaining your new equipment. We'll also compare different brands and models to find the best option for your budget and needs. For more information on mini tractors with backhoes, see this helpful [resource](https://mini-tractor-with-backhoe.pages.dev).

Backhoe or Front-End Loader: Which is Right for You?

The first decision is between a backhoe and a front-end loader. This choice depends largely on your needs and budget. A backhoe (an attachment with a digging arm at the rear) is ideal for serious digging tasks – post holes, trenching, and light foundation work. A front-end loader (an attachment with a bucket at the front) is more versatile, suited to moving materials like gravel, topsoil, or snow.

Budget Considerations: Front-end loaders often have a lower initial cost, though tractor modifications might increase the total expense. Backhoes typically have a higher upfront cost but are specialized tools for specific digging needs.

Assessing Tractor Compatibility: A Critical Step

Before purchasing any attachment, verify your tractor's capabilities. Consult your owner's manual to determine the following:

- Horsepower: Insufficient horsepower may lead to equipment failure.

- Hydraulic Flow Rate: This indicates the amount of hydraulic fluid your system can pump, directly impacting the attachment's performance.

- Lift Capacity: This dictates the maximum weight your tractor can safely lift, both for the attachment itself and any material moved. Exceeding this limit is dangerous.

Ignoring these specifications could result in damage to your tractor or injury to you.

Selecting the Ideal Attachment: A Detailed Comparison

Choosing the right attachment involves considering multiple factors:

- Digging Depth (Backhoes): This matters significantly for tasks requiring deep holes. Deeper digging usually means a higher price.

- Lift Capacity (Both): This determines how much material the attachment can move safely. Overloading is dangerous and may cause damage.

- Ease of Installation: Some attachments are easier to install than others. Consult manufacturer instructions.

- Brand Reputation: Established brands like Bradco are known for quality, but may cost more than lesser-known brands.

- Warranty: A solid warranty protects your investment from unforeseen repairs.

Here's a simplified comparison (specific models will vary):

| Feature | High-End (e.g., Bradco) | Mid-Range | Budget-Friendly |

|---|---|---|---|

| Digging Depth | 8+ ft | 6-7 ft | 4-5 ft |

| Lift Capacity | 1000+ lbs | 750-1000 lbs | 500 lbs or less |

| Price | $$$ | $$ | $ |

| Ease of Install | Moderate to Difficult | Moderate | Easier |

Installation: A Step-by-Step Guide (Front-End Loader)

Installing a front-end loader is generally a DIY-friendly task, provided you follow the manufacturer's instructions carefully. For backhoes, professional installation is strongly recommended.

Front-End Loader Installation (General Steps):

- Secure the Frame: Attach the loader's frame to your tractor, ensuring correct alignment.

- Hydraulic Hookup: Connect the hydraulic lines, ensuring secure and leak-free connections.

- Attach the Lift Arms: Connect the lift arms to the loader frame and the tractor's lift points.

- Test Run: Before heavy use, test the loader to verify smooth operation.

Remember: Incorrect installation can cause serious damage or injury. Consult your manual and consider professional help if needed.

Prioritizing Safety: Essential Precautions

Safety is paramount. Always wear appropriate safety gear, including eye protection, gloves, and sturdy footwear. Carefully review both your tractor's and attachment's manuals. Never operate the equipment unless you are completely confident in your understanding of the procedures.

Maintenance and Troubleshooting: Extending Equipment Lifespan

Regular maintenance is crucial for longevity. Check hydraulic fluid levels, lubricate moving parts, and inspect for damage after each use. Addressing minor problems promptly avoids more costly repairs later.

Budgeting for Your New Attachment: A Comprehensive Breakdown

The total cost includes:

- Attachment Cost: The purchase price of the backhoe or front-end loader.

- Shipping Costs: Shipping heavy equipment can be expensive.

- Installation Costs: Factor in professional installation if needed (especially for backhoes).

- Tractor Modifications: You might need upgrades to your tractor's hydraulic system.

When Expert Assistance is Needed: Recognizing Limitations

Seeking professional help is wise in certain situations:

- Complex Modifications: Adapting attachments for non-standard tractors.

- Ballast Selection: Choosing the appropriate ballast ensures safe and efficient operation.

- Troubleshooting Difficult Issues: Persistent problems often require expert diagnosis.

By carefully considering all aspects -- from your tractor's capabilities to the specific requirements of your tasks – you can choose the right backhoe or front-end loader and significantly enhance the efficiency of your lawn care and small-farm operations.